A Beginner’s Guide to Bucket Elevators for Rice Mills

For any busy rice mill, efficiency is key—and that’s where the bucket elevator, also known as a rice mill elevator or elevator bucket conveyor, becomes essential. This vital equipment ensures a smooth and continuous workflow by vertically transporting materials such as paddy, milled rice, and bran using a series of buckets mounted on a conveyor belt or chain.

Key Components of a Bucket Elevator

- Buckets

These containers are attached to the conveying medium and are designed to scoop up and carry materials vertically. - Belt or Chain

The mechanism that drives the buckets. It allows for vertical movement and lifting to the desired height. - Trunks

The structural casing that encloses and supports the belt or chain system. Trunks are typically divided into upper, middle, and lower sections. - Hopper

Positioned at the elevator's base, the hopper holds bulk material before it's picked up by the buckets.

Types of Bucket Elevators in Rice Mills

Different applications require different types of elevators. Here’s a breakdown of the most commonly used types in rice milling:

- Continuous Bucket Elevator Buckets are spaced closely to form a continuous chain, minimizing spillage—ideal for fragile or granular materials.

- Positive Discharge Bucket Elevator

Uses centrifugal force for full material discharge. Offers high-capacity handling and efficient unloading. - Rice Mill Bucket Elevator

Tailored specifically for rice processing. Made with food-grade materials suitable for paddy, bran, and milled rice. - Industrial Bucket Elevator

Designed for heavy-duty operations and large-volume handling. Built for strength and durability. - Single Bucket Elevator

Features a single bucket for precision lifting. Suitable for specific, limited material handling applications. - Stainless Steel Bucket Elevator

Constructed entirely from stainless steel for maximum hygiene and corrosion resistance. Perfect for food, pharma, and chemical sectors.

Applications in Rice Mills

Bucket elevators play a crucial role in rice milling and other related industries:

- Grain Handling

They elevate grains for easy transfer and storage, streamlining bulk handling. - Rice Milling Process

Used throughout various milling stages—from cleaning to separation—ensuring smooth flow between machines. - Continuous Operation

Elevators designed for constant discharge maintain uninterrupted flow, increasing operational efficiency.

The Advantages of Bucket Elevators to Elevate Your Rice Milling Experience

In rice milling operations, efficiency, grain quality, and space optimization are critical. One of the most effective solutions that cater to these needs is the bucket elevator system. Widely adopted across rice mills, these systems offer numerous advantages that enhance productivity and ensure a seamless grain-handling process.

Key Benefits of Using Bucket Elevators in Rice Mills

- 1. Efficient Grain Handling

Bucket elevators streamline the rice-handling process by enabling smooth, continuous transportation of paddy or polished rice through various milling stages. Their automated design ensures consistent flow and reduces bottlenecks in production. - 2. Reduced Manual Labor

Automation via bucket elevators significantly minimizes the need for manual lifting and transporting of rice. This leads to increased productivity, reduced labor costs, and improved workplace safety. - 3. Gentle Grain Handling

Unlike other mechanical systems, elevator buckets are designed to gently transport rice, preserving the integrity of the grain. This reduces breakage and damage, maintaining high product quality. - 4. Space-Saving Vertical Design

With a vertical structure, bucket elevators optimize floor space, making them ideal for mills with limited horizontal room. Their compact footprint allows for more efficient plant layout and better workflow. - 5. Cost-Effective Operation Bucket elevators provide excellent value by balancing performance and investment. Their durability, low maintenance, and energy efficiency make them a smart, long-term solution for rice mills.

- 6. Seamless System Integration

They integrate effortlessly with other grain-handling and milling equipment, enabling a cohesive processing system that supports end-to-end efficiency. - Experience and Expertise

With decades of industry experience, Suri Engineers understands the specific demands of rice milling. Their elevators are engineered for robust performance and long-lasting durability. - Precision Engineering

Each elevator is crafted with attention to detail and built to withstand the rigors of continuous operation, ensuring maximum uptime and minimal maintenance. - Affordable Pricing

Suri Engineers offers competitive prices without compromising on quality. Their products deliver value by combining cost-efficiency with performance.

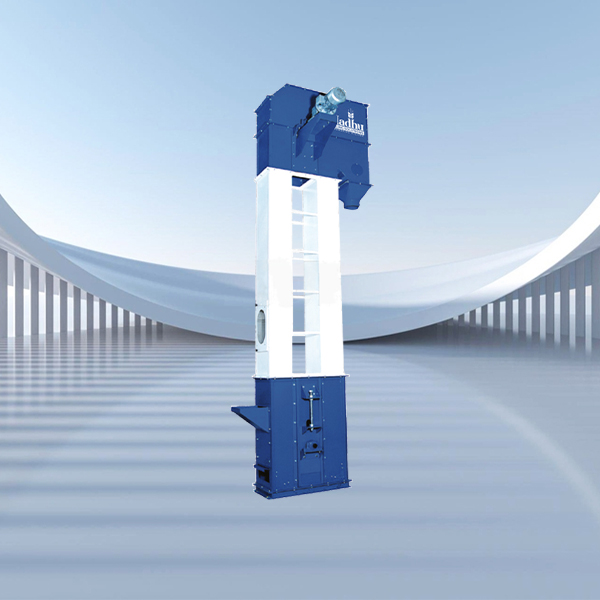

Why Buy Bucket Elevators from Madhu Milling?

When investing in a bucket elevator, choosing the right supplier is essential. Madhu Milling is a trusted name among bucket elevator and conveyor manufacturers, known for quality, reliability, and customer focus.