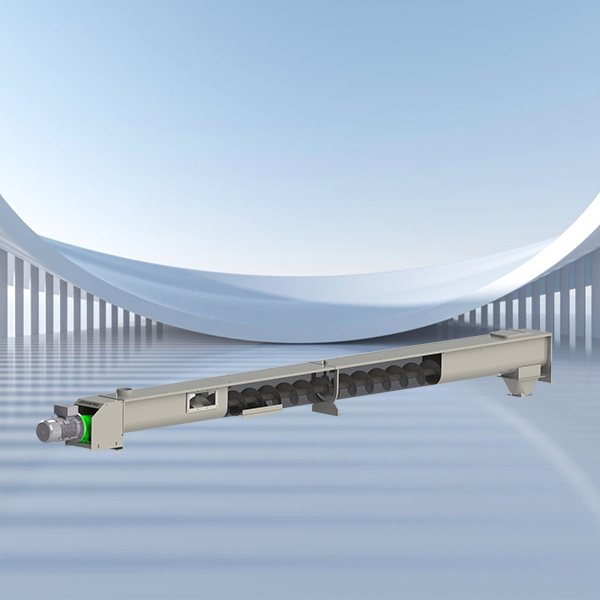

Screw Conveyors

Screw Conveyors

Highlights

- Spline shaft and bush arrangement for quick assembly and easy changeover.

- Suitable for horizontal, inclined, and vertical conveying applications.

- Manufactured in Mild Steel, Stainless Steel, and Galvanized Steel to suit various environments.

- Durable construction minimizing wear and tear of components.

- Handling capacities ranging from 2 TPH to 350 TPH.

- Rugged design ensuring low maintenance and extended machine life.

Technical Specifications

| Model |

Nominal Speed |

Capacity (Ton/Hour) |

| SC 150 |

60-80 |

3 |

| SC 200 |

60-80 |

6 |

| SC 250 |

60-80 |

10 |

| SC 315 |

60-80 |

20 |

| SC 350 |

60-80 |

30 |

| SC 400 |

60-80 |

50 |

| SC 500 |

60-80 |

75 |

| SC 600 |

60-80 |

100 |

Key Benefits:

- Designed with removable top covers and hinged bottom cleaning doors for easy, hassle-free maintenance and cleaning.

- Versatile for vertical transport of granular and powdered materials, mash, pellets, and flakes.

- Low power consumption relative to capacity, thanks to superior technical design and manufacturing.

- Minimum gap between trough and screw prevents material accumulation, ensuring hygienic, infestation-free operation with minimal residue.

- Modular design allows flexibility to adapt to specific client requirements.

- Safe operation enabled by automation safety sensors such as zero speed switches, choke-up, and overflow sensors.

- Equipped with aspiration points and spot filters to maintain dust-free working conditions.

- Compatible with explosion vents to enhance fire safety.

- Inspection windows for easy monitoring of equipment performance.

- Boltable design with gaskets ensures dust-tight protection.

- Ability to incorporate multiple inlets and outlets to maximize product utilization.

- Smooth and noise-free operation for a quieter work environment.

- High operational reliability for consistent, long-term performance.