Rice Sheller: Meaning, Types, & Uses

Rice shelling is a vital stage in the rice milling process where the outer husk or hull is removed from the paddy to extract the edible grain. This process is efficiently carried out using a specialized machine called a rice sheller or rice dehusker.

What is a Rice Sheller?

A rice sheller (also known as a rice husker) is a machine used to remove the tough outer husk from raw paddy grains. It reveals the rice kernel, which is the consumable part. Rice shellers play a crucial role in the rice milling industry by producing high-quality, market-ready rice.

What is Husking Rice?

Husking refers to the process of removing the outer hull of paddy rice. The rice sheller feeds the raw paddy into its mechanism, where the husk is separated from the grain. The dehusked rice is collected for polishing or further processing, while the husk is removed and discarded or used as byproduct fuel.

Types of Rice Shellers

Various types of rice shellers are used depending on the scale and automation required. Below are some common types:

1. Electric Rice Shelling Machines

These are automated machines ideal for high-capacity processing. They offer faster and more efficient husking compared to traditional manual methods.

2. Paddy Husker Machines

These machines specialize in dehusking unprocessed paddy grains. They are engineered to provide a high shelling percentage with minimal grain breakage.

Modern Rice Mill Sheller Machines

These machines integrate advanced features such as:

- Energy-saving mechanisms

- Durable components

- High-efficiency output

How Do Rice Shelling Machines Work?

The dehusking process involves several key steps:

- Feeding the Paddy: Raw paddy is fed into the sheller using a uniform feeding mechanism.

- Husking Process: Inside the machine, the paddy encounters rollers or rubber components that strip off the husk.

- Separation: The husk and the edible rice grains are separated.

- Output: Cleaned, dehusked rice is collected for polishing or packaging.

- Capacity: Choose a machine based on your processing volume.

- Power Source: Manual, electric, or fully automatic options are available.

- Durability & Build Quality

- Cost-Effectiveness

- Compatibility with Local Paddy Varieties

- After-Sales Support & Spare Parts Availability

- Maintenance Requirements

- Warranty Terms

- Advanced, durable rice dehusking machinery

- Consistent innovation for enhanced milling efficiency

- Nationwide service and support

Well-integrated sheller rice mills enhance efficiency, reduce grain damage, and increase yield.

Factors to Consider When Buying a Rice Shelling Machine

Before investing in a rice husker machine, evaluate the following:

Doing market research and checking customer reviews can help you make a well-informed purchase.

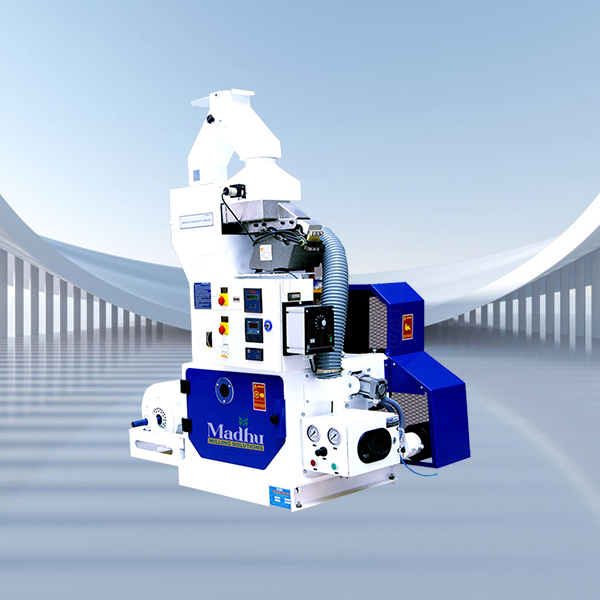

Why Choose Madhu Milling for Rice Shelling Machines?

Madhu Milling is a trusted name in the rice milling industry, offering:

They are known for their commitment to modernizing rice mills and helping millers achieve better yields and reduced processing costs.

Service Locations

Madhu Milling serves clients across India, including: Tamil Nadu Kerala Andhra Pradesh Karnataka Telangana Maharashtra Gujarat Madhya Pradesh Chhattisgarh Odisha West Bengal Assam Bihar Uttar Pradesh Rajasthan Haryana