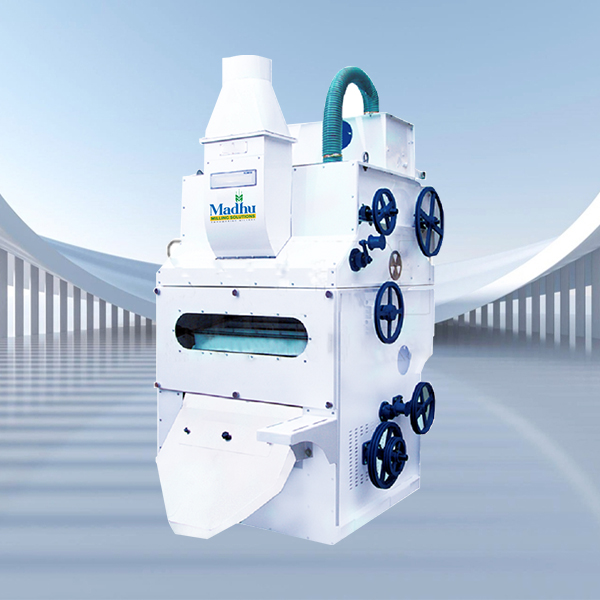

Paddy Cleaning Machines

The paddy cleaner is designed to remove finer impurities that remain after the initial pre-cleaning stage. It efficiently separates stones and other heavy contaminants from rice paddy using the principle of gravity.

Key Benefits of Paddy Cleaning Machines

- Integrated Dust Separation: Equipped with an inbuilt suction blower to effectively separate and collect dust, ensuring a cleaner work environment.

- Energy Efficient: Engineered for high efficiency while consuming significantly less power compared to older generation models.

- Robust Construction: Built with a heavy-duty structure that enhances rigidity, minimizes vibrations, and ensures a longer operational lifespan.

| Code No. | Product Name | Capacity on Paddy | Speed | Power Recommended | Dimensions (L * B * H in mm) |

|---|---|---|---|---|---|

| PC04F00 | PADDY CLEANER | 4 Ton/hr | 685 RPM | 3 HP/960 RPM* | 1850 * 1610 * 2600 |

An Overview of Paddy Cleaner Machines

Paddy cleaning machines are vital components in the rice milling process. These machines are engineered to efficiently clean and prepare paddy rice before it undergoes further milling. A typical paddy cleaning system includes a paddy cleaner and an integrated destoner unit.

What Do Paddy Cleaner Machines Do?

Paddy cleaner machines are designed to remove unwanted impurities such as dust, straw, chaff, and other foreign materials from raw paddy. The integrated destoner units enhance this cleaning process by efficiently eliminating stones and heavier debris, ensuring that only clean paddy moves forward for processing.

How Do Paddy Cleaners Work?

The cleaning process begins when raw paddy is fed into the machine via a continuous feeding mechanism. The machine then uses a combination of:

- Vibratory sieving

- Air suction

- Gravity-based separation

These mechanisms collectively remove lighter particles (dust and straw) as well as heavier contaminants like stones and metal fragments. The destoner component works specifically by leveraging airflow and density differences to separate heavier particles from the lighter rice grains.

Why Choose Paddy Cleaner Machines from madhu milling?

Founded in 1974, madhu milling brings decades of industry expertise to rice milling technology. Our paddy cleaners are crafted with a deep understanding of both customer needs and the evolving demands of the rice milling industry.

Key Benefits of Choosing Suri Engineers:

- High-efficiency cleaning with minimal grain loss

- Robust construction for long operational life

- Advanced technology tailored to modern rice mills

- Proven performance and customer satisfaction across regions

- Contact us today to get the latest paddy cleaner machine prices and detailed product specifications.

Global Reach and Domestic Supply

Suri Engineers has established a strong presence both domestically and internationally, delivering high-quality rice mill equipment across India and to various countries worldwide.

In India, we supply to:

Tamil Nadu, Kerala, Andhra Pradesh, Karnataka, Telangana, Maharashtra, Gujarat, Madhya Pradesh, Chhattisgarh, Odisha, West Bengal, Assam, Bihar, Uttar Pradesh, Rajasthan, and Haryana.

Madhu Milling continues to play a pivotal role in modernizing rice mills, offering reliable machinery that enhances productivity and ensures superior grain quality.