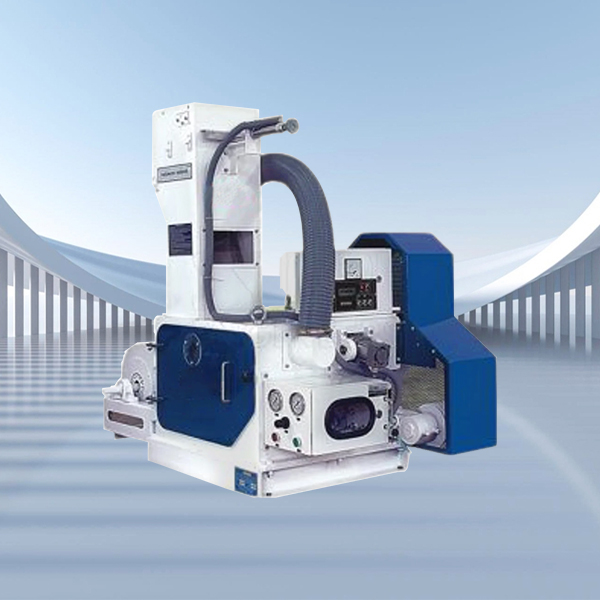

Pneumatic Paddy Dehusker Machine

This high-efficiency machine is designed for de-husking rice paddy and features two rubber rolls that rotate in opposite directions. The friction generated within the crushing chamber enables the machine to achieve shelling efficiency of up to 95%.

Key Benefits:

Automatic Shelling Activation: Integrated with a precision sensor that automatically starts and stops the shelling mechanism based on the presence of paddy, ensuring energy efficiency and reducing wear.

Adjustable Pressure Mechanism: Features a movable arm that adjusts dynamically towards the fixed arm, based on preset pressure levels, allowing for consistent and uniform de-husking.

Dual Operating Modes: Offers both automatic and manual operation modes, providing flexibility for various operational preferences and needs.

| Code No. | Product Name | Capacity on Paddy | Speed | Power Recommended | Dimensions (L * B * H in mm) |

|---|---|---|---|---|---|

| RS5F00 | PNEUMATIC HUSKER | 3-4 Ton/hr | 1270 RPM | 10-12.5 HP/1440 RPM | 1500 * 1000 * 1300 |

Brief Introduction

A pneumatic husker is a specialized machine widely used in the agricultural industry to remove husks from grains such as rice, wheat, and barley. This essential process ensures clean, husk-free grains, ready for consumption or further processing. By using compressed air for control and operation, pneumatic huskers offer greater efficiency, precision, and ease of use compared to traditional methods.

How Does a Pneumatic Husker Work?

Feeding Mechanism:

Paddy is fed into the husker through a continuous feed system that ensures uninterrupted processing.

Husking Chamber:

Inside the chamber, rubber rollers rotate at controlled speeds, creating friction that separates the husk from the grain.

Air Pressure System:

Adjustable compressed air pressure enhances the husking process and simultaneously blows away the separated husk particles, resulting in clean rice output.

Why Choose Madhu Milling’ Pneumatic Huskers?

Superior Build Quality:

Manufactured using premium-grade materials and advanced technology, ensuring durability and consistent performance.

Effortless Operation:

User-friendly design with automatic and manual modes for flexible operation.

Exceptional Customer Support:

Madhu Milling’ experienced team provides end-to-end support, from consultation and purchase to after-sales service.

Where Are Madhu Milling’ Huskers Available?

Madhu Milling has earned a strong reputation in the rice milling industry, supplying pneumatic huskers to leading rice mills across India and international markets. Indian Coverage: Tamil Nadu Kerala Andhra Pradesh Karnataka Telangana Maharashtra Gujarat Madhya Pradesh Chhattisgarh Odisha West Bengal Assam Bihar Uttar Pradesh Rajasthan Haryana International Markets: Bangladesh Nepal Sri Lanka

Madhu Milling is also expanding in emerging rice-producing regions with a growing demand for advanced milling technologies.